Corrugated Paper/Kraft Paper/Cardboard Paper/Testliner Paper/Fluting Paper/ Recycled Paper Making Machine

Basic Info.

| Condition | New |

| Transmission Type | AC Motor Variable Frequency Speed Regulation Segme |

| Rail Gauge | 4700mm |

| Main Market | Egypt, Iran, Afihan, Mexico |

| Final Industry | Paper Mill |

| Raw Material | Waste Paper, Waste Carton Paper, Recycled Paper |

| Capacity | 80-100t/Day |

| Working Speed | 120-200m/Min |

| Trimmed Width | 3600mm |

| Basis Weight Width | 100-160 G/M2 |

| Paper Grade | Kraft Paper, Testliner Paper |

| Transport Package | 1. Fixed All The Movable Parts with Plastic Films. |

| Trademark | HY |

| Origin | China |

| HS Code | 8439200000 |

| Production Capacity | 10 Sets Per Year |

Product Description

Corrugated Paper/Kraft Paper/Cardboard Paper/Testliner Paper/Fluting Paper/ Recycled Paper Making Machine

Paper Machine Buying guide

In order to recommend paper machine and make detailed technical proposal for you as soon possible ,please tell usthe following technical parameters:(1)what kind of paper do you want to produce?(2)what kind of raw material you will use?(3)how many tons do you want to produce per day(24hours)?(4)what is the output paper width of jumbo roll?--mm;(5)What is the output paper weight(thickness)?--gsm.Thanks for your cooperation!

Kraft Paper Making Machine Technical parameters:

| Main products | Fluting paper Corrugated Paper Testliner Paper Kraft Paper Duplex Board Paper |

| Test liner Ration | 90-150g / m2 |

| Capacity | 200t/d |

| Net paper width | 3800mm |

| Gross paper width | 3860mm |

| Working speed | 250-380 m / min |

| Design speed | 400 m / min |

| Gauge | 4900 mm |

| Roll of dynamic balance | G2.5 |

| Cylinder of dynamic balance | G4 |

| Batch-off roll of dynamic balance | G1.6 |

| Drive mode | AC motor variable frequency speed regulation segment drive |

| Paper machine layout form | Single layer layout |

| Pattern | Left hand machine |

| Banner moisture difference | ≤±1% |

| Banner quantitative difference | ≤±1.5% |

Dryness of Craft Paper

| Paper dryness out of wire part | 20-22% (± 1%) |

| Paper dryness out of press section | 44-46% (± 1%) |

| Before sizing | 92% |

| Paper roll machine | 92% |

| Lateral shrinkage | About 3.5% |

Fresh water, clarified water

| Requirements | clear, colorless, sand removal |

| Water pressure | 3.0MPa, 2.0MPa, 0.5MPa |

| PH value | 6-8 |

Power Supply

| AC voltage | high pressure,380/220V±5% |

| Control point pressure | 220/24V |

| Frequency | 50HZ±1% |

Printing Paper/A4 Paper/Wrinting Paper Making Machine

| Main products | Printing Paper/A4 Paper/Wrinting Paper/Copy Paper |

| Paper weight | 60-90g / m2 |

| Capacity | 5-100t/d |

| Net paper width | 1092-3200mm |

Paper Machine Raw Material

Paper is sorted into different grades such as waste paper, old carton box, reed, wheat straw, bamboo, bagasse, newspapers, duplex, white cutting, boards, core pipes, etc suitable for manufacturing different grades of Fluting paper Corrugated Paper Testliner Paper Kraft Paper Duplex Board Paper.

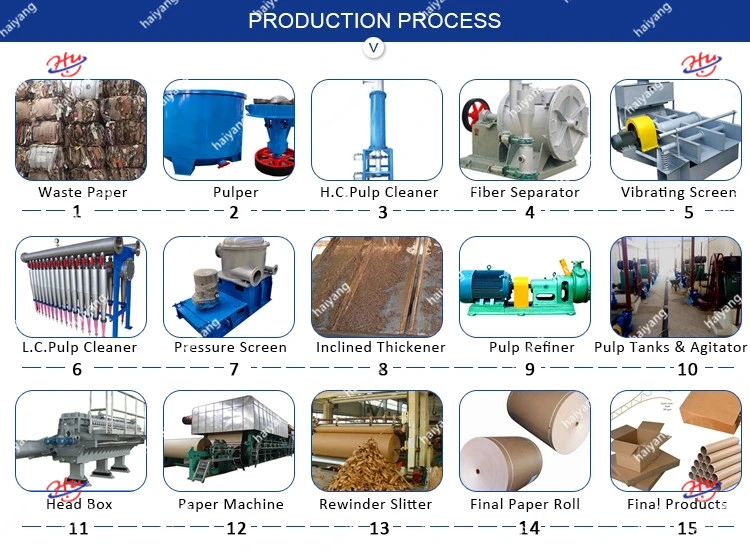

Paper Machine Process Flow

Paper Machine Wire Section

At the wet end of the paper machine sits the headbox, which distributes a uniform jet of watery stock. The liquid falls onto the wire or forming fabric. Beneath the wire, foils (short for hydrofoils) remove water and improve fibre uniformity, ensuring that the fibres weave together in a tight mat. The wire passes over suction boxes that vacuum out the water, leaving a soft mat of pulp that forms the paper sheet, also known as the paper web. By now the wire has travelled 30-40 meters. In a couple of seconds, the water content has dropped to 75-80%, and the web has lost its wet sheen.

Paper Machine Press Section

The next stage of water removal consists of passing the paper web through a series of nip rollers that squeeze the water out of the pulp mat. This pressure also compresses the fibres so they intertwine to form a dense, smooth sheet. At this stage, the water content has reduced to between 45 and 55%.

Paper Machine Drying Section

The paper web now travels through an enclosed space containing a number of steam-heated drying cylinders. They are warmed up to 130ºC using steam heat to ensure that the paper is now 80 to 85% dry. Wet sizing solution is now applied to the paper in order to add a thin layer of starch to the surface. Starch contributes to stiffness and the bonding of the fibres within the sheet of paper. After the sizing is applied, the paper passes through another set of heated drying cylinders. In all, the paper web may travel 400 meters through the dry end. In the process, it will lose roughly 93% of its water.

Paper Machine Finishing

To give the containerboard a smooth and glossy surface to optimise it for printing, the paper passes through a set of smooth rollers, which can be hard or soft, that press the paper, embossing a smooth face on the paper surface.

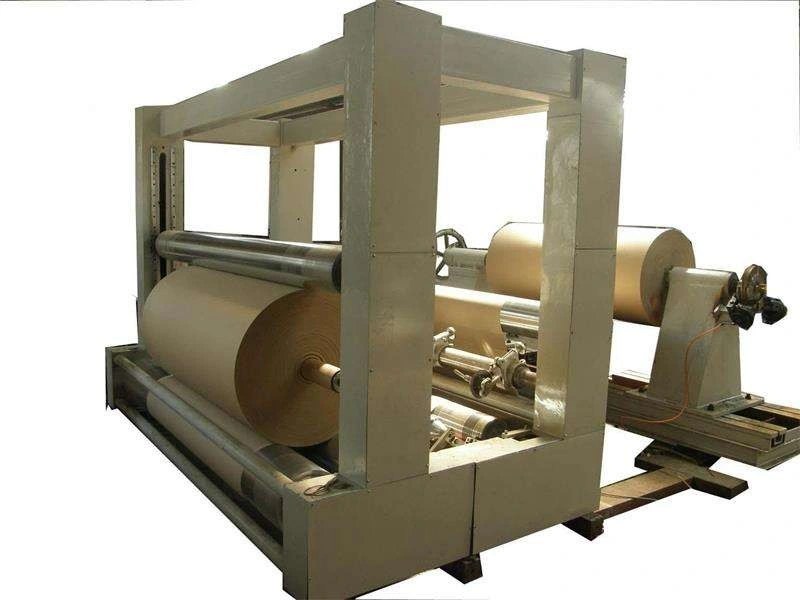

Paper Machine Winding

After completing its 500-metre journey, the paper exits from the paper machine and is automatically wound onto a jumbo reel, which can weigh 50 tonnes and be up to eleven metres wide. The jumbo reel is lifted by crane to a nearby winder, where the paper is unwound and cut into smaller rolls as required by the customer.

Company Profile

Since 1989 Qinyang City Haiyang Papermaking Machinery Co., Ltd has been established who is specialist in manufacturing a wide range of Paper Machines for Kraft, Test liner, Fluting paper, Corrugate, Writing & Printing, Newspaper, Duplex Board. We have more than 30 years expertise lies in applying state of the art technology to provide cost effective custom designed solutions to suit their varied requirements. The main series of the products are tissue paper machine; kraft paper/testliner /fluting paper machine;writing paper machine and special paper machine,etc. This company provides customers high efficiency and practical paper making production line with low carbon environmental protection thought. At present, our products have been sold to more than twenty provinces, cities and autonomous regions in domestic region and exported to Vietnam,Egypt, Bangladesh,Malaysia,Pakistan,Iran and other countries.

Packing & Delivery1. Kraft Paper Making Machine Fixed all the movable parts with plastic films.2. Polystyrene foam plate wrapped around.3. Wrapped with tight plastic films several circles.4. Fixed machine on the fumigated plywood pallet with iron wire.5. Wrapped with wooden board around and nailed on.

Our service

Pre-sale Service----24 hours phone, email, trade manager online services;----We will supply the detailed project report, detailed general drawing, detailed flow process design, detailed layout factory drawing for you until meet your requirement;----we welcome you to come to our paper making machine factory and paper mill factory to have a look and check;----We will tell you all the necessary cost when set up a paper mill factory;----We will answer you all the questions within 24 hours;----We will send you various quality paper samples made by our paper machine for free;----We can supply turn key-project service.On-purchase Service----We will accompany you to check all the equipment made by us, and help you to make the plan of installation;----We will supply paper machine assembly drawing, the foundation and foundation load diagram, transmission diagram, formal installation drawing, use and installation instructions and a full set of technical data after signing the contract.After-sales Service----We will delivery the machine as soon as possible according to your requirement, within 50 days;----We will send rich practiced experience engineers to you to install and test the machine and train your worker for free;----We will give you one year guarantee time after the machine can run well;----After one year, we can guide and help you to maintain the machines;----Every 2 years, we can help to overhaul the complete machines for free;----We will send you spare part in lower price.

FAQ

1. What kind of paper machine your factory produce?Our factory mainly produce flowing machine:A. Kraft paper machine which can produce carton box paper, corrugated paper, craft paper, testliner paper, carton board paper etc.B. Culture paper machine which can produce white paper jumbo roll, include A4, A3 paper, copy paper, printing paper, newspaper, offset paper etc.C. Toilet Paper Machine which can produce toilet paper, tissue paper jumbo rollD. Paper processing machine. the jumbo roll paper can be processed all kinds of paper, such as , A4, A3paper, handkerchief paper, towel paper and kitchen using paper2. Can you make paper mill design for us?Yes, we have a technician team of 116 engineers and 12 experts with more than 20years experience.3. How about your machine quality, we are worry about the quality?FRD is a mature brand in china, more than 30 years manufacuturing experience of different kinds of paper machines. We strictly manufacture and manage according to IOS9001:2008 System, and can match all the CE standard or more strict standard. our paper machine is running well in more than 20 countries. we are gold supplier on alibaba already 5 years.4. What should I have to know if I want to get the quotation?a. What kind of raw material you will use(main important)b. The capacity you want produce per day(main important)c. The paper weight you require.d. The paper width you require.5. Your machine price is high, is there any discount?We always provide high quality paper machines, we are paying more attention on oversea market, because of communication time after sales, and also it need very long time to send new parts. our paper machines have enough quality standard to make sure the machine can work more than the real warranty period. our marketing style is quality=price and price=quality, the price will be acceptable for our clients and durable for our machines. anyhow, when we will negotiate the price with each other during our meeting in factory, and get a good satisfaction.6. Could your engineer can teach and train our workers and stay in our factory for long time?Yes, we have 116 technical installation engineer team, they can train and teach your worker to operate paper machine, but you should pay them salary.