2ply Flute Paperboard Making Machinery Production Line

2ply flute paperboard making machinery production line 1.Electric Mill Roll Stand Structure and Features : 1,Symmetrical;

Basic Info.

| Model NO. | CZXY-1600-280 |

| Sheet Cutter Type | Computerized |

| Application | 2ply Cardboard Making |

| Flute Type | a, B, C, E Optional |

| Stacker | Attached with Sheet Cutter |

| Mill Roll Stand | Electric |

| Corrugated Rollers Diameter | 280mm |

| Single Facer Speed | 60m/Min |

| Heating Type | Electric Heating |

| Width | 1600mm |

| Transport Package | Plastic Film, Container. |

| Specification | Unilateral maximum load: Maximum 3000 kg |

| Trademark | Xiaoyuan |

| Origin | Cangzhou City, Hebei Province |

| HS Code | 8441809000 |

| Production Capacity | 10-15sets/Month |

Product Description

2ply flute paperboard making machinery production line

1.Electric Mill Roll Stand

Structure and Features :

1,Symmetrical structure,can carry two kraft paper at one time,which can work without brake.

2,Reel paper lift-lower, clamp, loosen, movement, contraposition operated by electric mechanic.feeding kraft / reel paper quickly.

3,Brake: pneumatic brake, simple & useful.

Spec of stand :

1, Reel Stand driven by electric

2, Kraft paper range:

Width: Max: 1600mm Min:700mm

Diameter: Max: Φ1400mm

Max Weight:2000Kg(One side)

2.280mm Fingerless Type Single Facer

Glue Rollers:

| Diameter | Φ215mm |

| Processing Way | Surface of glue roller is grinded,then with 25 line rut type net dot,then plating chromeSurface of glue banlance roller is grinded then plating chrome |

| Control Way | Pneumatic cylinder control of the Lifting Up-down |

Corrugated Rollers:

| Diameter | Φ280mm |

| Material | 48CrMo high quality alloy steel,rigidity HRC60° |

| Processing Way | Through hardening and tempering→inside hold boring→roller heading connecting→weld→tempering to low the stress→ meticulous turning→rough grinding→mid frequeney induction hardening→Nc meticulous grinding→chrome plating. |

| Flute Type | (U/V) ACBE as customer's requirements |

Press Rollers:

| Diameter | Φ284mm |

| Material | medium steel (MS)45# |

| Processing Way | The surface is grinded then plating chrome, hardening and tempering(With Buffer) |

| Control Way | Penumatic cylinder control of the Lifting Up-down |

Preheater Rollers:

| Diameter | Φ320mm |

| Material | seamless steel tube |

| All connected by flexible metallic tubes | |

| About gear | Close style gear transmission oiliness lubricated, long use life of gear |

Common Spec:

| Machinery Speed | KnightΦ280:100 m/min |

| Width of Paper | 1400mm |

| Style of Transmit cardboard | Vacuum Cover adsorbable style,Hight pressure Draw fan.with wind control Adjusting & noise deadening device. |

| Style of Control Roller | Pneumatic control the upper roller, pressure roller and glue roller |

| Lubrication | Anti-high temperature lube to lubricate the Corrugated Roller and Press Roller's gears |

| Power | 7.5 kw |

| Pneumatic & Electric control systems are in one operation counter, Distance between main machine no less than 1.5m | |

| Wallboard: cast iron,thickness:130mm | |

3.computerized sheet cutter&stacker

| parameter/specification | unit | 1400 | 1700 | 2000 |

| Max cutting width | mm | 1300 | 1600 | 1900 |

| Cutting rannge | mm | 400--2400 | 400--2400 | 400--2400 |

| Cutting thickness | mm | 1--2 | 1--2 | 1-2 |

| Power | kw | 6 | 6 | 6 |

| Working speed | m/min | 80 | 80 | 80 |

Delivery pictures:

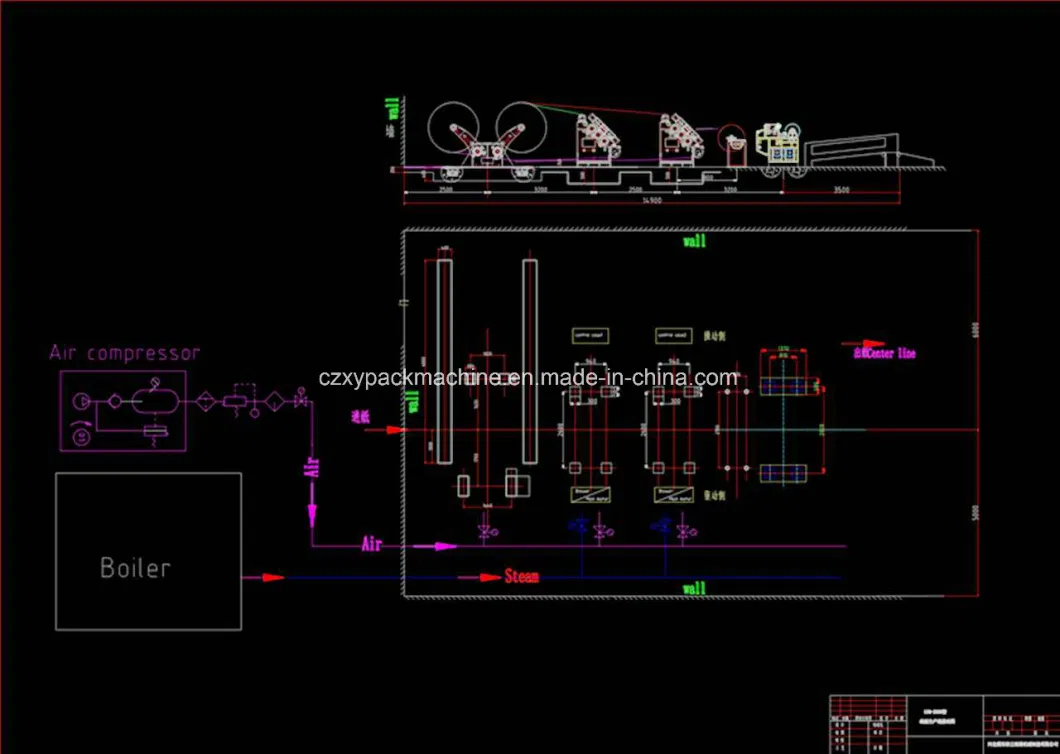

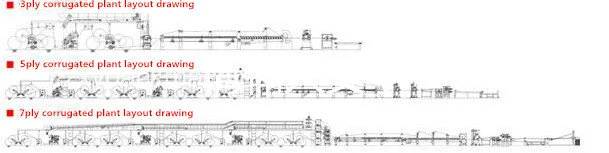

Layout Picture:

2ply corrugated line:

Carton Making Process:

Welcome to contact us, I'm Sara, looking forward to meeting you!Website: http://czxypackmachine.en.made-in-china.com

You may also like

Send inquiry

Send now